|

|---|

| STOCKED ITEMS | EXCESS INVENTORY | TOOLS & MACHINERY | ABRASIVES | BUFFS & COMPOUNDS | GRINDING EXTRAS & SAFETY ITEMS |

ALL MANUFACTURERS |

|---|

Midwest Sandright Wet Wide Belt Sanders

Nautilus 2

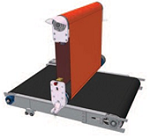

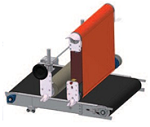

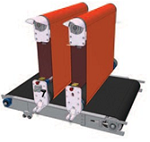

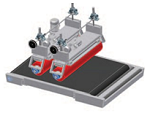

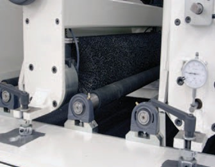

| NAUTILUS 2 WET DEBURRING & FINISHING MACHINES Nautilus 2 Wet Deburring and Finishing Machines are designed for the industrial user to economically deburr and/or finish a wide variety of component parts made from either sheet metal or steel plate. Designed with constant pass line height and a rugged split frame, the Nautilus 2 will provide years of dependable service. A 6-inch diameter contact drum(s), and up to 12-inch diameter Scotch Brite™ brush ensure precision results. Available in single and two head configurations, and in 37 and 52-inch wide models. Made in USA. |

Machine Configurations  Belt  Belt Brush  Belt Belt  Brush Brush |

STANDARD FEATURES |

|

| OPTIONAL EQUIPMENT • HMI/PLC controls with color monitor • Electronic variable speed belt/brush control Note: includes forward/reverse brush head rotation • Forward/reverse brush head rotation • Adjustable contact drum with eccentric bearing • Special conveyor belt with smooth splice to minimize telegraphing • Small parts magnet • Vacuum bed • UL Approved electrical panel |

|

|

|